Integrated solution of adipic acid production

We provide you with the know-how & equipment for adipic acid production of 5-20 TPA

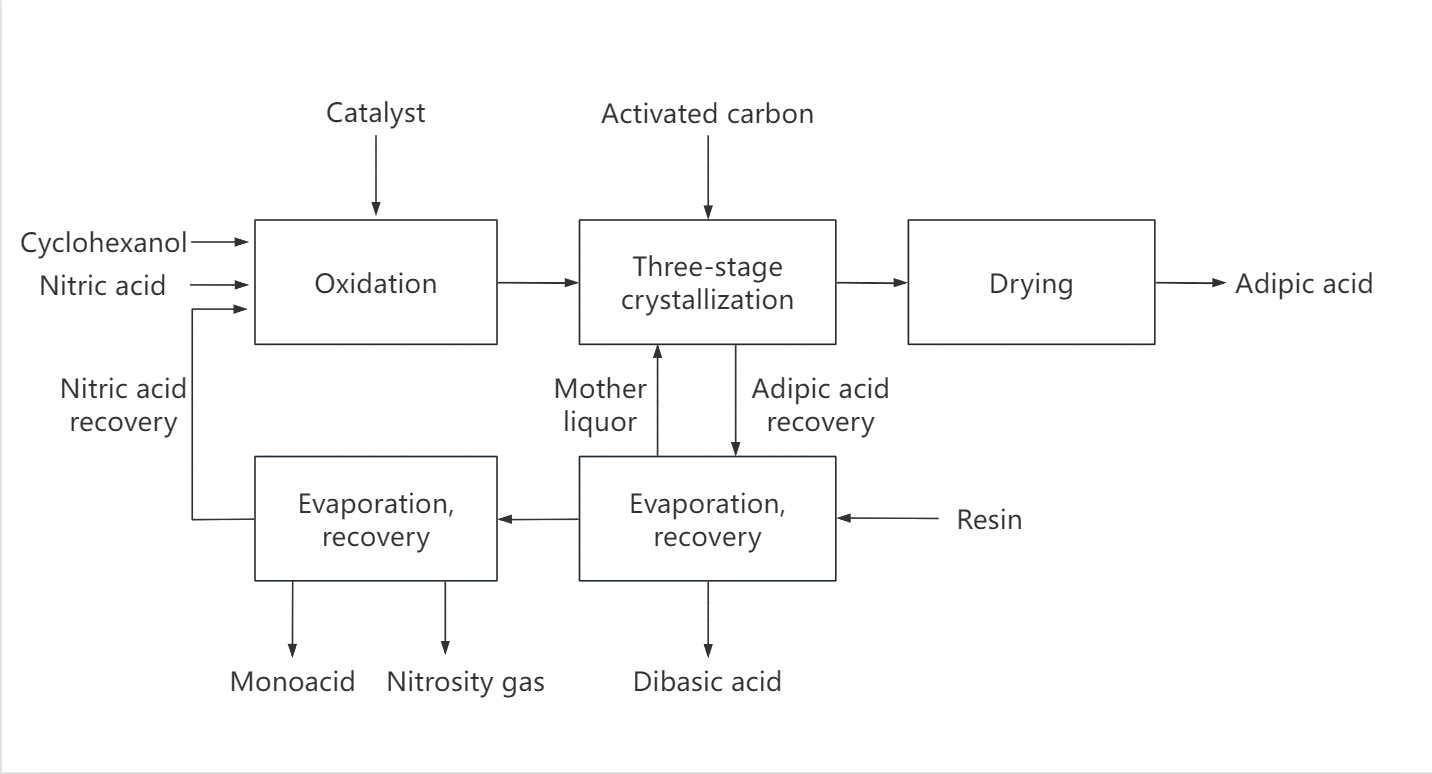

Tianli refined adipic acid unit uses nitric acid and cyclohexanol as raw materials. Copper and vanadium are used as catalysts for oxidation to produce adipic acid. The entire process route includes oxidizing acid preparation, oxidation reaction, crude adipic acid crystallization and separation, dissolution and decolorization, refined adipic acid crystallization and separation, nitric acid recovery, mother liquor acid concentration, dibasic acid removal and catalyst recovery, super refined adipic acid crystallization and separation and drying, dibasic acid slicing and other production steps.

The process characteristics are reflected in the following aspects:

1.The reactor with the largest production capacity that has been successfully applied in China is used, and the temperature, agitator power and cyclohexanol feed pump are interlocked to ensure production safety;

2.The crude adipic acid crystallizer is optimized to make the crystallization temperature gradient more conducive to adipic acid crystallization;

3.The dibasic acid waste liquid discharged from the adipic acid recovery section is evaporated and concentrated, and then dibasic acid slicing is performed to transform the original dibasic acid waste liquid into a by-product, thereby improving the comprehensive economic benefits of the device;

4.The cold mother liquor and pure water systems of the device were optimized, and some of the original pure water users switched to using cold mother liquor, saving the pure water consumption of the device.