LIST

PRODUCTS

Contact us

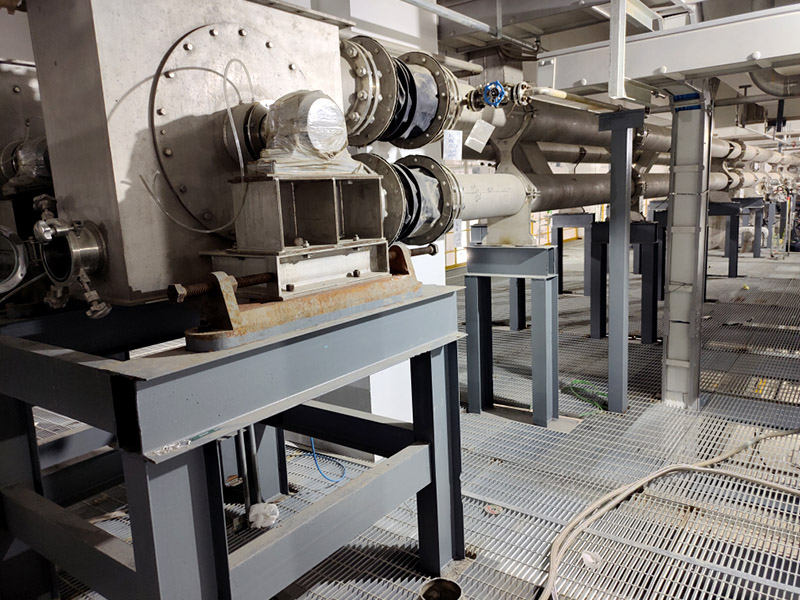

Pipe Chain Conveyor

- Tianli

- China

Equipment Structure

Equipment Structure

1. Conveying pipeline system

Structural design: Seamless steel pipe or stainless steel pipe (304/316L) is used as the conveying pipeline, and the inner wall of the pipe is polished, and the resistance coefficient is reduced by 20%. The pipeline connection adopts a quick-release clamp structure, which is convenient for disassembly and assembly, and supports 90° horizontal/vertical turns and inclined conveying layout.

2. Chain drive system

Chain structure: High-strength alloy steel or stainless steel chain links are used to increase tensile strength.

Drive device: Equipped with servo motor (protection level IP65) and helical gear reducer. Equipped with overload protection sensor, it automatically stops when the load exceeds the set value.

3. Feeding and discharging system

Feeding device: discharge valve, screw feeder or gravity feeding port, the feeding port is equipped with pneumatic sealing gate to prevent dust from overflowing.

Discharging device: A pneumatic valve or rotary discharger is set at the bottom to support multi-point unloading design and realize flexible material distribution.

4. Intelligent control system

PLC + touch screen control, integrated current sensor, blockage alarm, temperature monitoring module, etc.

Working Principle

1. Feeding stage

The material is quantitatively fed into the feed port of the pipeline through the discharge valve or screw feeder, and the pneumatic gate ensures the sealing of the feeding process to prevent dust leakage.

2. Conveying stage

The drive motor drives the chain to operate, and the chain plate forms a continuous thrust in the pipeline to push the material along the inner wall of the pipeline. The material moves forward in an overall flow state in a confined space to avoid stratification, crushing and dust problems.

3. Discharging stage

When the material reaches the designated discharge port, the pneumatic valve opens and the material is discharged under the action of gravity. By controlling the opening and closing sequence of each discharge port, accurate material distribution and multi-point unloading can be achieved.

4. Cleaning and maintenance

The system supports online cleaning function, which can quickly remove residual materials in the pipeline through compressed air blowing or reverse chain operation.

Core Technology Advantages

1. Excellent closed conveying performance

The fully enclosed pipeline design prevents dust from spilling. For flammable and explosive materials, a nitrogen protection system can be configured to ensure safe transportation.

2. Flexible layout adaptability

It can realize horizontal, vertical, inclined and combined transportation, which is suitable for complex plant layout. It has good performance for materials with poor fluidity and heat-sensitive materials.

3. Low wear and low energy consumption design

The non-contact operation of the chain plate and the inner wall of the pipeline reduces the material breakage rate.

4. Intelligent operation and maintenance system

The vibration sensor monitors the operating status of the equipment in real time and warns of faults such as bearing wear and chain loosening in advance. Provide installation drawings and operation manuals to support remote debugging and fault diagnosis.

Applicable Materials

Basic chemical raw materials: sodium carbonate, ammonium sulfate, sodium bicarbonate, ammonium chloride, potassium chloride, diammonium phosphate and other salt materials, as well as the transportation of soda ash and caustic soda (flake or granule).

High-molecular polymer: such as polyethylene particles, polypropylene particles, polyvinyl chloride resin powder, etc. During the transportation process, the pipe chain conveyor can avoid static electricity generated by friction of materials, prevent polymer particles from sticking, and ensure the stability of material quality.

Catalysts and additives: such as petrochemical catalysts and plastic additives. The low breakage rate and precise transportation characteristics of the pipe chain conveyor can reduce material loss and waste, while preventing external impurities from mixing in and ensuring product quality.

Battery materials: lithium battery positive electrode materials (lithium iron phosphate, ternary precursors).