LIST

PRODUCTS

Contact us

Spin Flash Dryer

- Tianli

- China

Main Introduction

Main Introduction

Flash dryer is a vertical dryer with rotary pulverizing device, which can simultaneously dry, pulverize and classify materials. It is for filter cake, paste and muddy material drying.

Working Principle

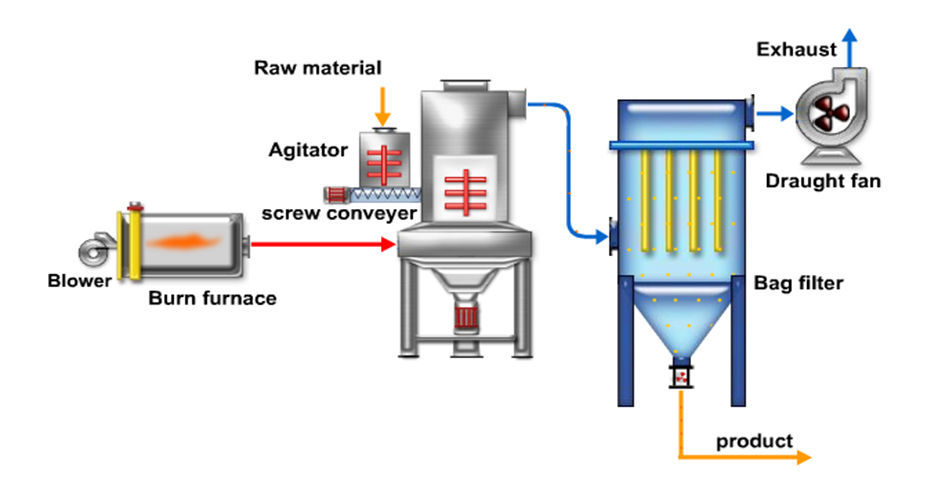

The clean thermal medium heated by the heat source enters the drying chamber in a tangential form, forming a powerful vortex swirling airflow with the mechanical agitation mechanism. The wet material is metered into the drying chamber by a feeder, pulverized and dried by stirring and vortex flow. The top of the drying chamber is set with a particle size classifier. The fine powder that meets the drying requirements is discharged from the top of the tower and collected by the latter separator. The larger particles that do not meet the drying requirements are blocked by the classification ring, returned to the drying chamber, and continue to be pulverized and dried. The dried materials are carried out of the spin flash dryer by the exhaust gas and enter the cyclone. After the primary dust collection by the cyclone, part of the materials enter the bag filter along with the exhaust gas. In the bag filter, all the materials are collected. The materials collected by the cyclone and the bag filter are then conveyed into the pneumatic conveying system through the discharge valve. Under the action of the pneumatic conveying fan, materials are sent to the final product silo for temporary storage, and then enters packaging system.

Specification

Specification | Diameter(mm) | Evaporative Capacity((kgH₂O/h) | Installed Power(kw) | Height(m) | Area(m*m) | Temperature(℃) | Others |

GSX-300 | Ф300 | 20~50 | 2.2~5.5 | 4 | 3.8*2.7 | 120~350(high temperature flash can reach 550) | Heat source: gas, steam, electricity, coal, oil, etc. |

GSX-500 | Ф500 | 30~100 | 5.5~7.5 | 5 | 4*3 | ||

GSX-600 | Ф600 | 40~200 | 5.5~7.5 | 6 | 4.3*3.2 | ||

GSX-800 | Ф800 | 60~600 | 11~22 | 6.5 | 4.5*3.5 | ||

GSX-1000 | Ф1000 | 100~1000 | 11~22 | 7.5 | 4.8*3.8 | ||

GSX-1200 | Ф1200 | 150~1300 | 11~22 | 8 | 5*4 | ||

GSX-1250 | Ф1250 | 150~1400 | 15~18.5 | 8 | 5*4 | ||

GSX-1300 | Ф1300 | 180~1400 | 15~45 | 8.5 | 5.1*4.1 | ||

GSX-1400 | Ф1400 | 200~1600 | 15~45 | 9 | 5.3*4.3 | ||

GSX-1600 | Ф1600 | 250~2500 | 30~45 | 9.5 | 5.5*4.5 | ||

GSX-1800 | Ф1800 | 300~2500 | 30~75 | 10 | 6*5 | ||

GSX-2000 | Ф2000 | 400~3200 | 45~75 | 11 | 6.5*5.5 | ||

GSX-2400 | Ф2400 | 500~4000 | 45~90 | 12 | 7*6 |

Advantages and Characteristics

1. In view of the operating characteristics of the flash dryer, the material thickness selected by our company's equipment is relatively high. Our company's material selection is based on ensuring the stable operation of the equipment, reaching production standards, and ensuring the service life of the equipment;

2. Our company uses solid round steel to make the scattering shaft, and the special structure design makes the scattering teeth embedded and fixed;

3. On the scattering shaft, the dynamic balance problem is avoided, the equipment runs stably, the maintenance frequency is low, and the equipment has a long service life;

4. Our company has mature engineering experience in this material, accurate selection, and ensures product output and quality;

5. Our company has a lot of successful experience in related materials, and has exclusive technology in the design and processing of core components (such as: scattering shaft design, scattering tooth design), and has the advantages of high strength, easy maintenance, and good dynamic balance.

Applicable Materials

Has been widely used in fine chemicals, dyes, pesticides and intermediates, food and metallurgy ore industry. Such as magnesium hydroxide, aluminum hydroxide, alumina, molecular sieve, 4A zeolite, white carbon black, dibasic acid, mancozeb, silica gel, stearate, various carbonates, various heavy metal salts, etc.