LIST

PRODUCTS

Contact us

Cyclone

- Tianli

- China

Equipment Structure

Equipment Structure

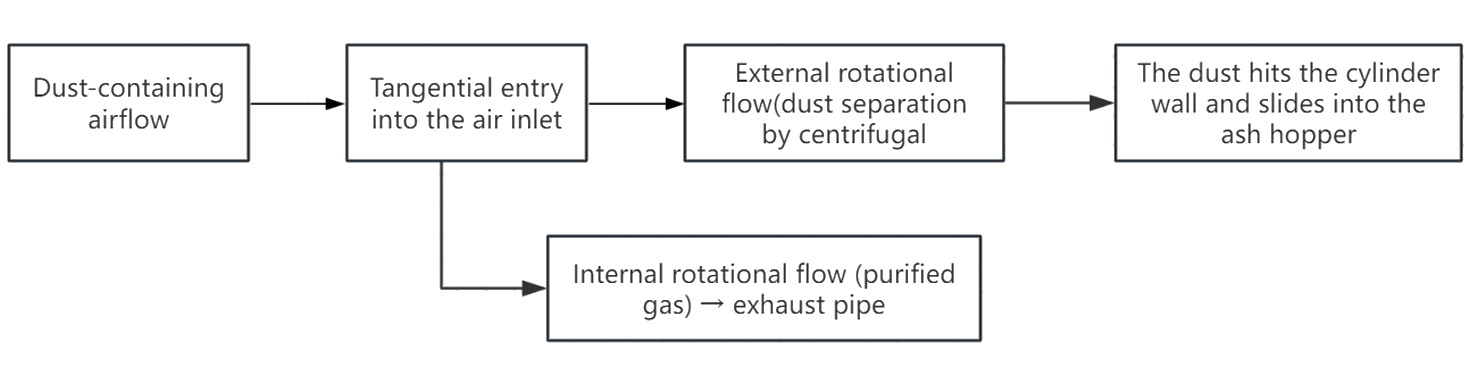

Cyclone is a dry dust removal equipment that uses centrifugal force to separate dust granules in the airflow. It is a high-efficiency mechanical dust removal device. Its core principle is: after the dust-containing airflow enters the cyclone, it makes a spiral rotation along the cylinder wall (forming an “external vortex”), and the dust granules are thrown to the cylinder wall under the action of centrifugal force, and after separation from the airflow, they slide along the wall surface to the ash hopper;the purified gas forms an upward “internal vortex” in the central area and is discharged from the exhaust pipe.

Key Structural Components

Air inlet: mostly rectangular or circular, the airflow enters in a tangential direction, forming a rotating motion.

Cylinder and cone: The cylinder is cylindrical, the cone is an inverted cone, and the bottom is connected to the ash hopper to ensure smooth dust collection.

Exhaust pipe: located at the top center of the cylinder, it guides out the purified gas.

Ash hopper and ash unloading device: collect dust and prevent air leakage (air leakage will reduce dust removal efficiency)

Technical Features

Advantages | Specific Presentations |

High dust removal efficiency | The dust removal rate for particles with a diameter of ≥10μm can reach over 90%, which is suitable for the purification of medium and coarse dust particles. |

Simple structure and low cos | There are no moving parts, so it is easy to maintain. The equipment investment and operating costs are lower than those of bag dust collectors or electrostatic dust collectors. |

Wide range of applications | It can handle high temperature, high humidity, corrosive gases, and is wear-resistant (such as dusty environments in the metallurgical and cement industries) |

Easy to operate | No complex control system is required, it can be directly connected to industrial pipelines and is suitable for continuous operation. |

Influencing Factors And Measures

Inlet wind speed: Too high wind speed will increase resistance loss, too low wind speed will result in insufficient centrifugal force. Tianli makes reasonable selection through calculation and adopts tapered air inlet (such as rectangular tapered structure) when necessary to reduce airflow impact loss.

Dust particle size and density: The larger the particle size and the higher the density, the higher the dust removal efficiency. Tianli adds guide vanes according to the characteristics of different materials to improve airflow distribution and reduce resistance.

Diameter and height of cylinder: The smaller the diameter, the greater the centrifugal force and the higher the efficiency, but the air volume is limited; increasing the height can extend the airflow residence time and improve efficiency.

Application

It can be used as the rear gas-solid separation device of spray dryers, fluid bed dryers, rotary dryers and other equipment to capture product powder. It is also commonly used for flue gas dust removal in hot air drying furnaces. It can be used for the primary separation of larger particles in high-temperature flue gas discharged from rotary kilns (such as calcined dust of carbon black, iron phosphate, catalysts, etc.)

Can be used in the following industries:New energy: catalysts, cobalt tetraoxide, waste battery materials, lithium carbonate, iron phosphate, ternary precursors, carbon black, etc.

Chemicals: ABS, AAS, PP, PE, PMMA, POM, PC, CPE, CPP, PVC\CPVC\EPVC, PVDF, PVDC, PAM, adipic acid, nylon 66, etc.

Salt chemicals: potassium chloride, potassium sulfate, sodium nitrite, magnesium chloride, magnesium sulfate, salt, nitrate, soda ash, baking soda, sodium percarbonate, calcium chloride, ammonium chloride, zinc chloride, ammonium sulfate, etc.

Metallurgy: copper concentrate, sponge copper, sponge iron, lead concentrate, zinc concentrate, etc.

Environmental protection: sludge, oil sludge, biomass slag, etc.