LIST

PRODUCTS

Contact us

Fluid Bed Dryer With Built-In Heat Exchanger

- Tianli

- China

Main Introduction

Main Introduction

Internal heated fluid bed dryer is a new drying technology developed on the basis of traditional fluid bed dryer by indirect heating drying.

Working Principle

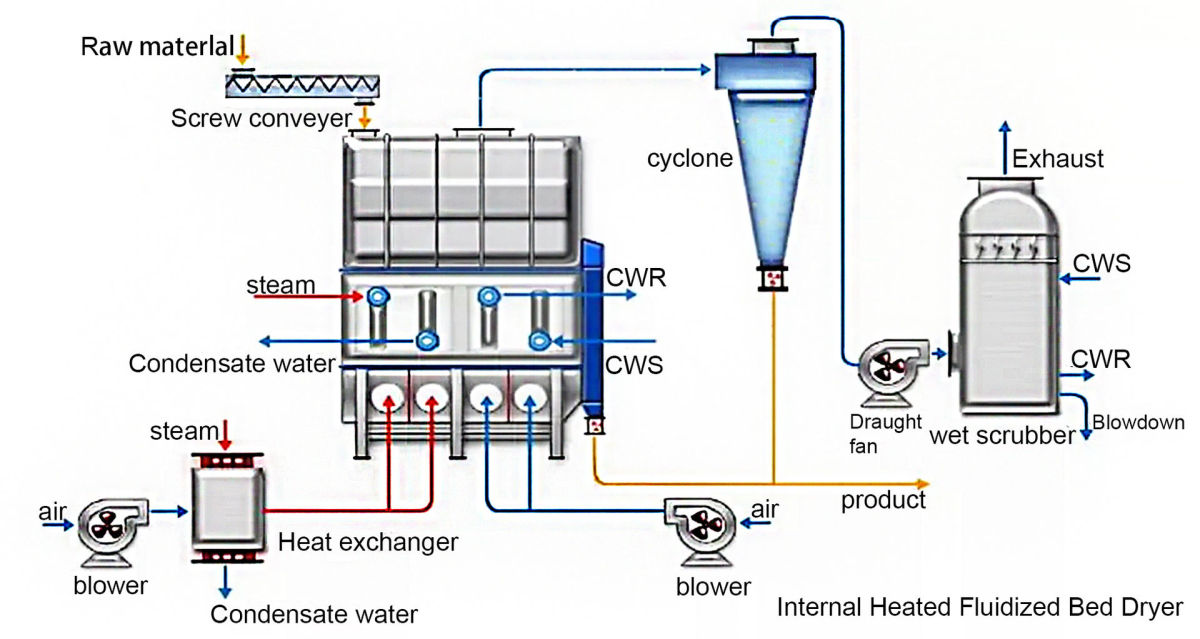

Fluid bed dryer with built-in heat exchanger is a new drying technology developed on the basis of conventional fluid bed drying and indirect heating drying. It immerses the tube or plate heat exchanger in the fluidized dry material, and meeting the material fluidization requirements with the smaller air volume. The fluidized medium mainly plays the role of carrying water to maintain normal fluidization of dryer particles. The drying (cooling) process is mainly the heat transfer between the built-in heat exchanger and the two-phase flow, and the heat and mass transfer processes between the two-phase flow.

The internal heated fluid bed dryer is divided into the upper and lower bed body, the air distribution plate, the inlet and outlet ports, etc. And its difference from ordinary fluid bed dryer is that a built-in heat exchanger is set up in the fluidization section of the lower bed body, and the heat source of the heat exchanger can be steam or heat transfer oil, etc. Since most of the heat is supplied by a built-in heat exchange device with high heat exchange efficiency, the hot air is mainly used as a power medium for ensuring normal fluidization, and the demanded amount of hot air is greatly reduced than normal fluid bed dryer.

Specification

Type | Dehydration Capacity | Installed Power(kw) | Steam Pressure(MPa) | Dimensions(Length × Width × Height) (mm) |

GWLN5.0 | 300~1200 | 40~80 | 0.1~2.0 | 4000×1500×5000 |

GWLN8.0 | 500~2000 | 60~120 | 0.1~2.0 | 7000×1500×6000 |

GWLN10.0 | 600~2500 | 80~160 | 0.1~2.0 | 7000×1800×7000 |

GWLN20.0 | 1200~5000 | 150~320 | 0.1~2.0 | 13000×1800×7000 |

GWLN30.0 | 1800~7000 | 250~450 | 0.1~2.0 | 15000×2000×7000 |

GWLN45.0 | 3000~11000 | 300~700 | 0.1~2.0 | 13000×4200×7000 |

GWLN60.0 | 4000~14000 | 450~900 | 0.1~2.0 | 15000×4200×7000 |

GWLN70.0 | 5000~16800 | 500~1100 | 0.1~2.0 | 15000×5000×7000 |

GWLN80.0 | 6000~19000 | 650~1300 | 0.1~2.0 | 20000×5000×7000 |

Characteristics

1. Efficiency in energy saving is high. Most heat is provided by the in-bed heat exchanger with the efficiency about 90%, hot air is used mainly to ensure normal fluidization, the quantity of hot air is much less than that needed by conventional fluid bed dryer; power consumption and heat losses of the exhaust air are accordingly reduced, resulting in higher drying efficiency.

2. As gas flow velocity in the system is lower than that in the conventional fluid bed dryer, so the material being entrained from the fluid bed dryer by the air is reduced significantly, the load of the dedusting system is reduced and the environmental protection is improved correspondingly.

3. Use of a special air distributor to prevent material leaking.

4. Easy to install, simple to operate, inexpensive to maintain.

5. Integration of drying and cooling bed, small floor space, low investment.

Design experience in various industries

Tianli provides various drying systems under harsh working conditions, such as:

1.In the chemical industry, a closed-circuit drying system with nitrogen as the medium

has been built;

2.In the coal chemical industry, has built a closed-circuit system with superheated steam as the medium;

3.In the inorganic salt industry, it provides a technical upgrade plan for the closed-circuit drying system with HCL as the medium.;

4.In the metallurgical industry, manufactured the dryer with medium working condition of 600°C;

5.In the catalyst and lithium battery industries, built the drying system with a working temperature of 1000°C;

6.Designed and manufactured the largest fluid bed dryer in China (with an area about 80 m²).

Applicable Materials

Adipic acid, soda ash, refined salt, sodium percarbonate, anhydrous sodium sulphate, potassium chloride, potassium nitrate, ammonium chloride, ammonium nitrate, ammonium sulfate, calcium chloride, calcium hypochlorite, calcium sulfate, granulated porcelain clay, Granulated fertilizer, iron sulfate, potassium carbonate, potassium chlorate, potassium phosphate, potassium tartrate, sludge, sodium hydrogencarbonate, sodium bromide, sodium chlorate, sodium formate PVC, CPE, PC, etc.