LIST

PRODUCTS

Contact us

Steam Straight Tube Rotary Dryer

- Tianli

- China

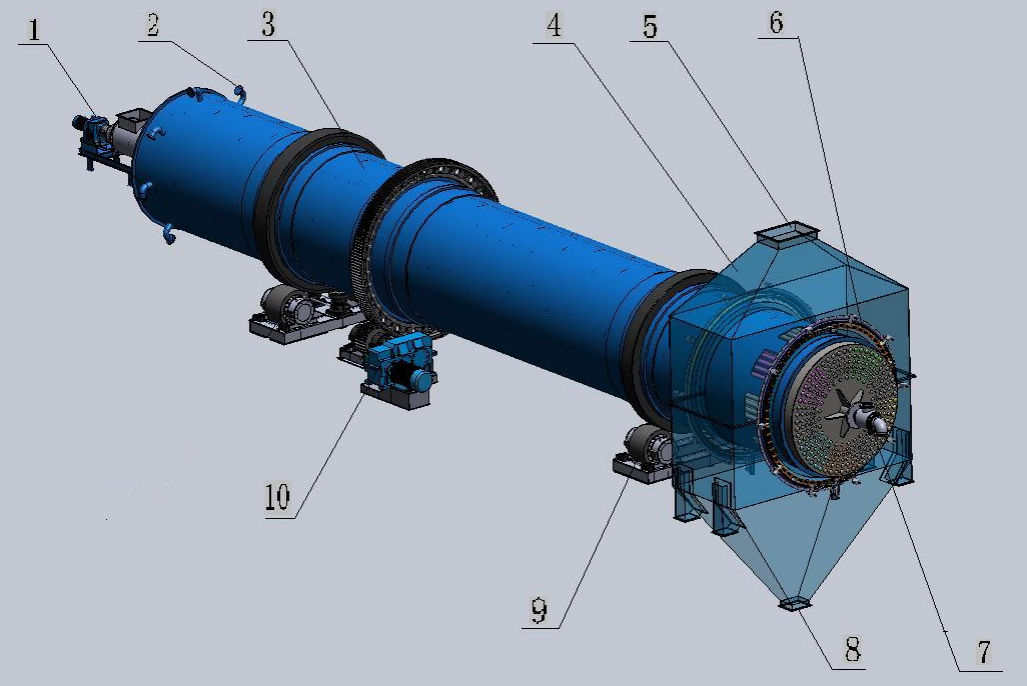

Equipment Structure

Equipment Structure

The steam straight tube rotary dryer is composed of several key components. The feeding device is located at one end of the cylinder, usually using a feeder or a screw conveyor, which can achieve quantitative and uniform material transportation while effectively preventing heat from escaping from the cylinder. The beating device immediately adjacent to the feeding end vibrates periodically to prevent the material from caking or blocking at the feeding port or the inner wall of the cylinder, ensuring a smooth drying process. The cylinder body is the core of the dryer. Multiple seamless steel pipes are arranged parallelly inside the cylinder as heating elements. Steam passes through these heating pipes to transfer heat to the materials. The inner wall of the cylinder is welded with scraper plates. As the cylinder rotates, the scraper plates continuously rise and sprinkle the materials, allowing for thorough heat exchange. The discharge cover and the discharge seal are located at the other end of the cylinder. The discharge cover receives the dried materials, preventing dust from spilling out and avoiding the entry of external air to affect the drying effect.

The rotary joint is a key component in the steam and condensation system. Its dynamic sealing structure ensures that saturated steam is safely and stably input into the heating pipe and that the condensed water is effectively discharged. The thrust and support roller device consists of a wheel group and a retaining wheel. The support roller supports the weight of the cylinder, while the thrust restricts the axial movement of the cylinder to ensure the smooth operation of the equipment. The transmission device is composed of a motor, a reducer, and a gear ring. Through the variable frequency speed regulation function, it can flexibly adapt to the drying requirements of different materials.

1.Material feed

2.Beating device

3.Cylinder

4.Discharge hood

5.Air outlet

6.Discharge seal device

7.Rotary joint

8.Discharge port

9.Thrust and support roller device

10.Transmission

Characteristics

1. Large heat transfer area, high thermal efficiency;

2. The processing capacity is large, single machine can reach 200t / h;

3. The equipment has good sealing performance, suitable for the recovery of organic solvents;

4. The structure is simple, easy to operate, low maintenance cost;

5. Good sealing, no dust leakage, less environmental pollution.

Specification

Specification | Length(m) | Heat transfer surface(m²) | Speed (r/min) | Slope (%) |

GZQ1200 | 9~14 | 90~140 | 0.5~5 | 1.5~3.5 |

GZQ1600 | 12~18 | 200~330 | ||

GZQ1800 | 14~20 | 250~480 | ||

GZQ2200 | 16~24 | 530~800 | ||

GZQ2600 | 18~28 | 840~1300 | ||

GZQ3000 | 24~30 | 1450~1800 | ||

GZQ3600 | 30~40 | 2000~2600 | ||

GZQ4000 | 35~45 | 2700~3000 | ||

GZQ4200 | 40~50 | 3200~3500 |

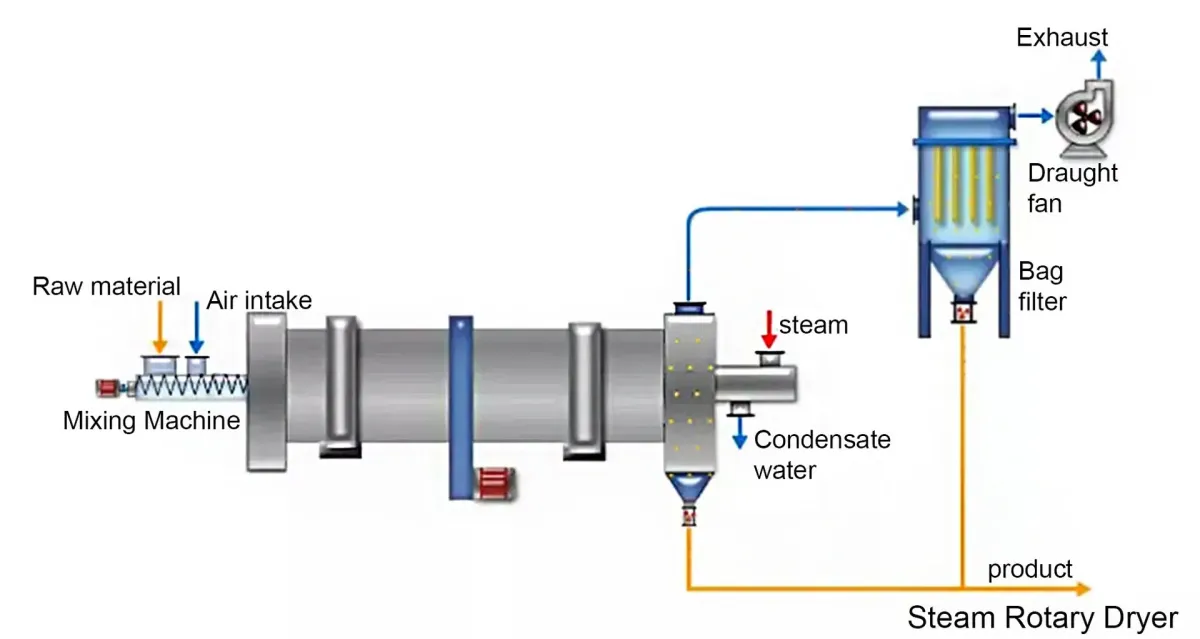

Working Principle

The Rotary dryer with straight steam distributor is a widely used equipment. Its interior is equipped with heat exchange tubes that provide the necessary heat for drying. These tubes are arranged at regular intervals around the circumference of the dryer. Saturated steam circulates inside the tubes, while the material flows outside the tubes. Heat is indirectly transferred through the tube walls between the steam and the material, causing the moisture within the material to evaporate, thereby achieving the drying function.

Features

Features of Rotary dryer with straight steam distributor:

A large number of tubes are used as the main heat exchange surface, which has a larger heat exchange area;

The tube spacing of the heat exchange tube can be flexibly set to effectively prevent the material from clogging at the feed port;

The equipment has high thermal efficiency, and the material is fully in contact with the tube in the equipment for heat exchange, which increases the contact area, increases the dispersion of the material, and enhances the heat transfer effect;

The wear-resistant lining plate of the cylinder wall can be easily replaced, which reduces the wear of the cylinder wall and prolongs the life of the equipment;

The equipment has a large processing capacity, is suitable for continuous operation, is stable and reliable, and has great operational flexibility ;

It only takes away the moisture-carrying gas of the volatile components, the gas consumption is small, and the dust recovery equipment is simple.

Applicable Materials

Applicable materials: the steam rotary dryer can be widely used in industries such as chemical engineering, petrochemical engineering, light industry, metallurgy, building materials, and environmental protection.

Chemical Industry: sodium carbonate, light ash, heavy ash, ABS resin, aluminum hydroxide, PC, urea, calcium magnesium phosphate fertilizer, melamine, ammonium sulfate, ammonium nitrate, ammonium chloride, sodium chloride, sodium sulfate, potassium chloride, calcium chloride;

Petroleum and Chemical Industry: polyolefins, Vinyl Chloride, Pentaerythritol, CTA, PTA;

Environmental-friendly building materials: coal slime, lignite, bituminous coal, coke powder, desulfurized gypsum, sludge;

Metallurgy: copper concentrate powder, iron concentrate powder, nickel concentrate powder, lead concentrate powder, scar removal sand.