LIST

PRODUCTS

Contact us

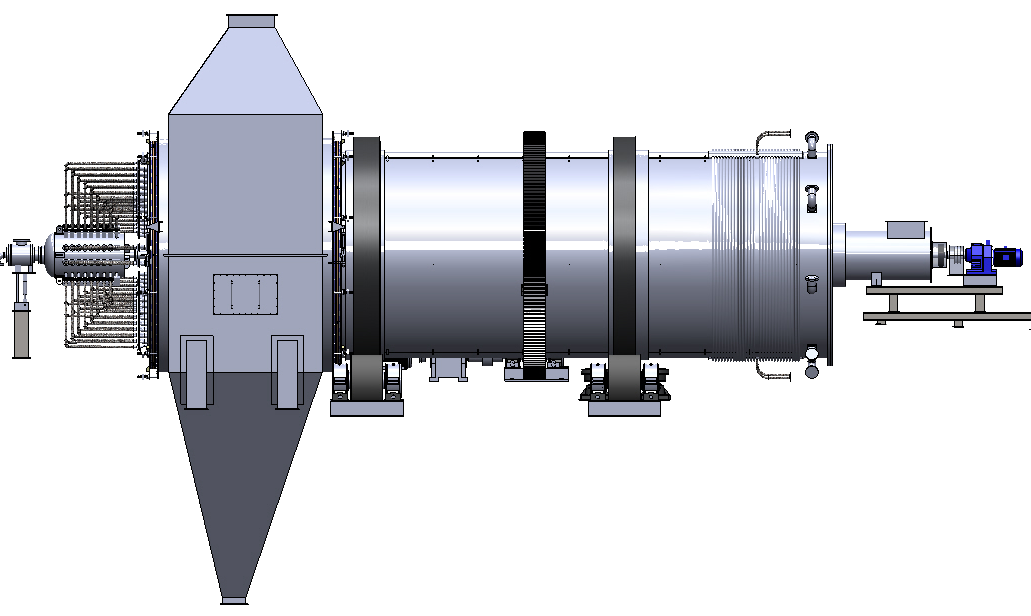

Steam Circular Tube Rotary Dryer

- Tianli

- China

Main Introduction

Main Introduction

The main body of the steam circular tube dryer is a rotating cylinder. Inside the cylinder, there are multiple concentric heating elements arranged in a circular pattern throughout the interior of the dryer. The heating elements are made of 316L/S22053 material and are transparent tubes. The heating tube elements are special components consisting of two relatively thick main pipes and several thin pipes vertically welded to the main pipes, arranged in a stepped shape. All the heating elements are equally divided into five parts in the cross-sectional direction of the cylinder. Each heat exchange component can be removed as a whole from the cylinder to facilitate maintenance and replacement of the heating tubes. The process of removing the heat exchange tubes is simple and easy. It has the advantages of large heat exchange area, high effective heat exchange area utilization rate, good wear resistance, convenient maintenance and repair, and small floor space.

Working Principle

The materials from the upstream process enter the movable belt conveyor and are transported to the steam rotary dryer. After entering the dryer, the materials rotate with the cylinder and come into contact with the heating elements. Through various heat exchange methods such as convection, conduction, and radiation, the materials are dried. With the help of the slope of the dryer, they move from the higher end to the lower end and are finally discharged from the discharge rotary valve at the tail of the dryer. At the discharge end of the dryer, there is a regulating weir plate to adjust the filling rate of the materials inside the cylinder. Combined with the slope and rotation speed of the cylinder, it can meet the requirements for the residence time, filling rate and output of the material drying.

Specification | Power | Capacity |

ZTHG1606 | 11kW | 1.5t/h |

ZTHG1610 | 15kW | 2t/h |

ZTHG2008 | 30kW | 15t/h |

ZTHG3012 | 90kW | 90t/h |

ZTHG4411 | 160kW | 180t/h |

ZTHG4515 | 250kW | 220t/h |

Technical Features

The circular tube is the main heat exchange surface, and within the same cylinder volume, it has a larger heat exchange area;

The drying intensity is high, the single machine processing capacity is large, the equipment operates stably, and it is suitable for continuous production;

The equipment cylinder is shorter, with small deformation, and the equipment concentricity is high;

The spacing of the heat exchange tubes can be flexibly set to solve the problem of material fluidity and prevent blockage;

The heat exchange tubes are of detachable structure, making maintenance and replacement convenient. It only takes 4 hours to replace a set of heat exchange tubes;

The external heating device of the cylinder can effectively prevent wall sticking and scarring;

The heat exchange of the dryer is through the circular tube, and the material flows in parallel for heat exchange, reducing the wear of the heat exchange tubes by the material;

The installed power is small, the energy consumption is low, and the operating cost is low;

The cylinder inner wall is lined with wear-resistant lining plates, which can be easily replaced, reducing the wear of the cylinder wall and prolonging the equipment life.

Applicable Materials

Applicable materials: Steam circular tube rotary dryer can be widely used in chemical industry, petrochemical industry, light industry, metallurgy, building materials, environmental protection and other industries.

Chemical industry: calcium magnesium phosphate fertilizer, ammonium chloride, sodium chloride, sodium sulfate, potassium chloride.

Metallurgy: copper concentrate, iron concentrate, nickel concentrate, lead concentrate, scar removal sand.