LIST

PRODUCTS

Contact us

Ordinary Rotary Dryer

- Tianli

- China

Main Introduction

Main Introduction

Rotary dryer is a kind of drying equipment for processing large quantities of materials. It has characteristics of reliable operation, large operation flexibility, strong adaptability, large processing capacity, strong adaptability of materials, drying of various materials. It is widely used in building materials, metallurgy, chemical, cement industry to dry slag limestone, coal powder, slag, clay and other materials.

Working Principle

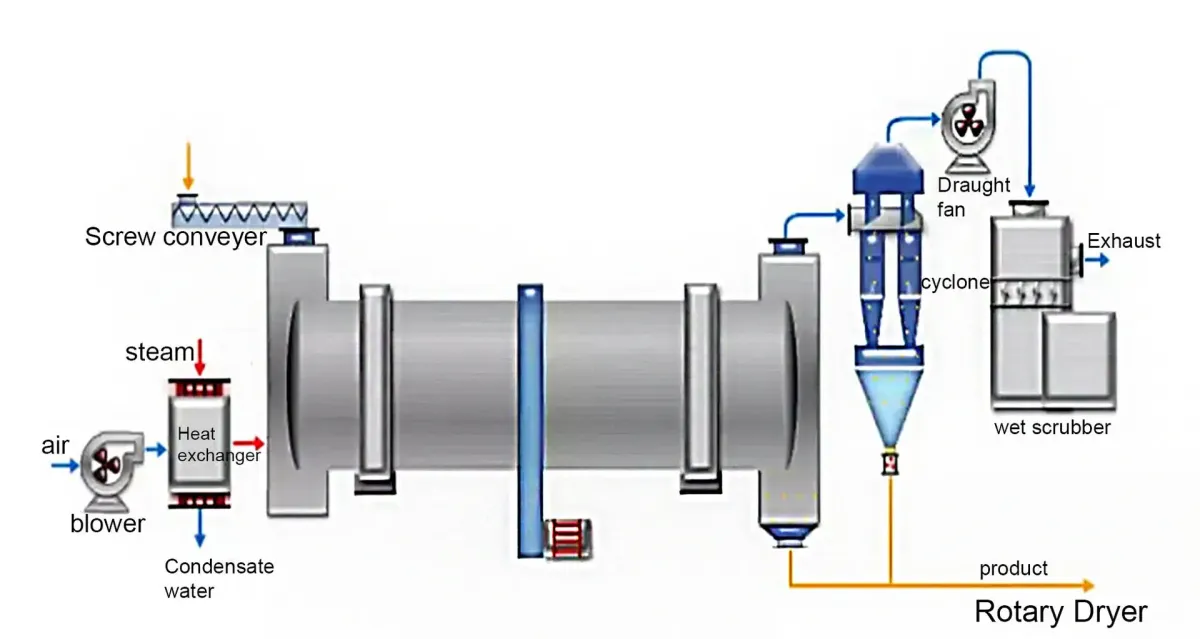

The rotary dryer, a key equipment in industrial drying, mainly comprises a rotating body, lifting plates, a transmission device, a supporting device, and a sealing ring. The rotating body, a cylindrical shell, is installed with a 3° - 5° inclination to the horizontal, which is crucial for material flow and determined by factors like material type and moisture content.

Material enters the dryer from the higher end of the cylinder, while the high-temperature heat source, such as hot air, flue gas, or steam, enters either in parallel or counter-flow. Parallel flow suits heat-sensitive materials for its gentle heating, whereas counter-flow offers higher heat transfer efficiency for materials tolerating high initial temperatures.

With the cylinder rotating at 2 - 8 revolutions per minute, the material moves to the lower end. The transmission device, including a motor, speed reducer, and drive system, powers the rotation. The supporting device, made of roller rings and rollers, ensures stable rotation and bears the load. Sealing rings at both ends prevent gas leakage and air ingress, enhancing energy efficiency.

Lifting plates, evenly distributed on the inner wall, lift material and let it fall in a curtain-like manner, increasing the contact area with hot air. This accelerates heat transfer, promotes moisture evaporation, and ensures uniform drying.

Once dried to the desired moisture content, the product exits from the lower end. Post-treatment processes like screening, cooling, and dust removal may follow to meet production and quality requirements. Precise control of temperature, rotational speed, and gas flow is vital for optimal drying results.

Specification

Specification | Length(m) | EvaporativeCapacity(kgH₂O/h) | Temperature(℃) | Speed(r/min) | Slope(%) |

HZ1200 | 10~14 | ~800 |

850℃ |

0.5~5 |

1.5~4 |

HZ1500 | 12~16 | ~1500 | |||

HZ1800 | 16~20 | ~2600 | |||

HZ2000 | 18~22 | ~3600 | |||

HZ2200 | 20~24 | ~5000 | |||

HZ2400 | 22~26 | ~6500 | |||

HZ2600 | 24~30 | ~8000 | |||

HZ2800 | 26~32 | ~9000 | |||

HZ3000 | 28~34 | ~10000 | |||

HZ3200 | 30~36 | ~11500 | |||

HZ3600 | 34~40 | ~14000 | |||

HZ4000 | 38~44 | ~19000 | |||

HZ4500 | 40~60 | ~25000 |

Characteristics

1. Large drying capacity.

2. Continuous, steady operation.

3. Adjustable rotating speed fitting the requirements of different materials.

4. According to different material characteristic, it chooses different inner structure to meet drying requirement of the materials.

5. Effective prevention of the material against sticking on the wall; an ideal system for drying of material with high moisture content and viscosity.

Applicable Materials

Widely used in chemical, mining, metallurgy, agriculture, feed, fertilizer and other industrial fields. Such as ore, slag, coal, metal powder, diatomaceous earth, kaolin, starch residue, distiller's grains, dregs, soy sauce residue, fertilizer, potassium chloride, potassium sulfate, etc., sludge, aquatic product waste, food factory waste, phosphorus fertilizer sulfur Ammonium, light calcium carbonate, clay, lime slurry, ore mud, phosphate rock slag, aluminum plant red mud.