LIST

PRODUCTS

Contact us

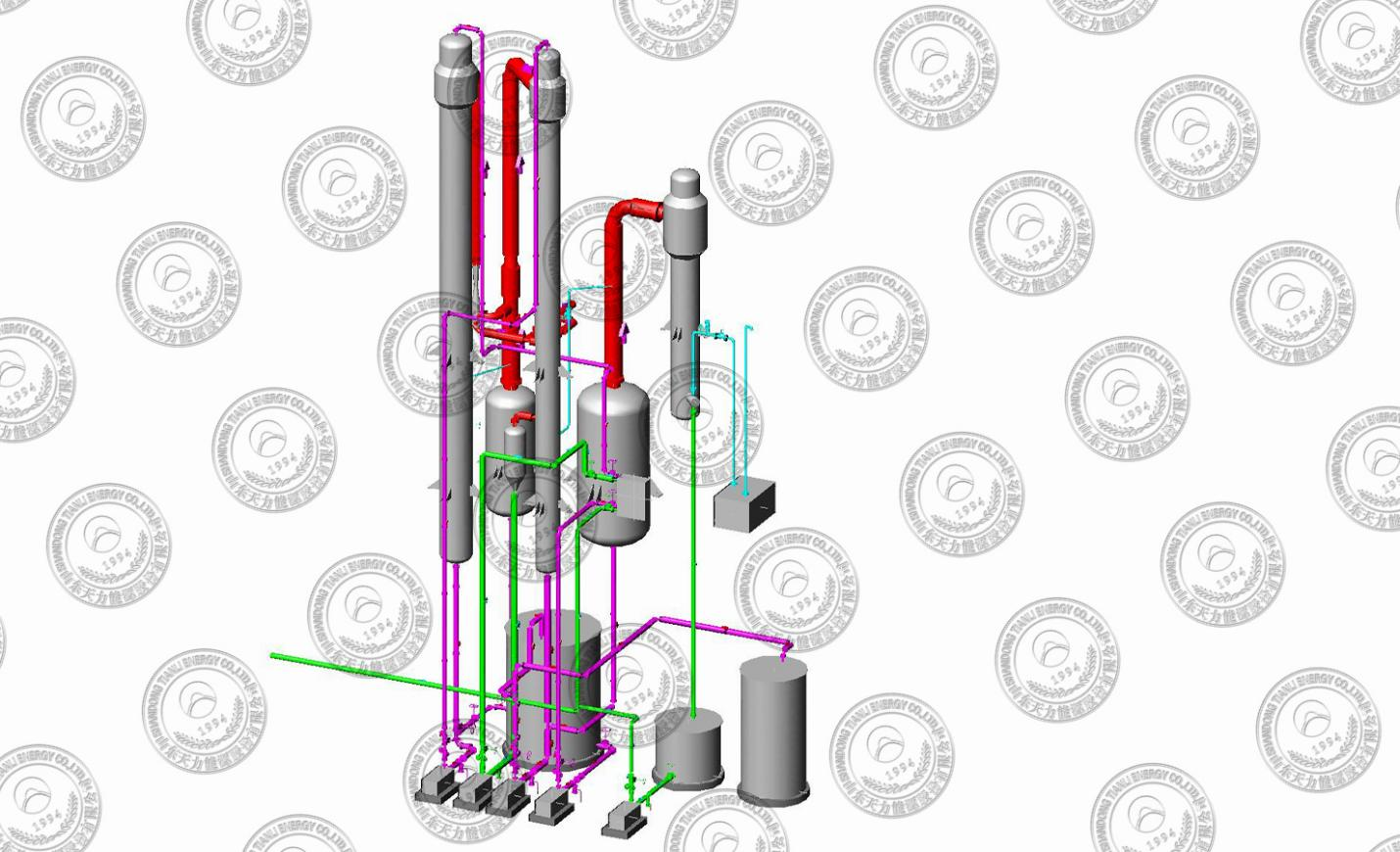

Direct Current (Circulation) Falling Film Evaporator

- Tianli

- China

Equipment structure

Equipment structure

The Falling Film Evaporator (FFE), with a capacity ranging up to 150 t/h and a relatively small floor - space requirement, is among the most widely used evaporators in the process industry due to its simple operation, the need for a low temperature difference, and high heat - transfer coefficients. It is particularly well - suited for temperature - sensitive products, liquids containing small quantities of solids, and those with a low to moderate tendency to form incrustations.

In an FFE, the liquid is fed into the top of the Shell and Tube Heat Exchanger. As it moves through the system, vapors are generated within the heating tubes. Both the liquid and the vapors flow in the same downward direction (co - currently). After that, they are conveyed to the separator located at the lower end of the heat exchanger.

The FFE is normally equipped with a liquid distributor in spreading the evaporator liquid in the form of a thin film. The resulting film is not only thinner but also moves more rapidly. This characteristic leads to a shorter contact time between the product and the system and a high rate of heat transfer.

Regarding the principle of operation: Volatile substances in the heating tubes are evaporated by creating a thin film. This film moves through the tubes under the influence of gravity, and vapors are continuously produced during this process.

Particular Features

Highly suitable for heat sensitive materials;

Fouling is minimized due to low tube wall temperature and heat flux;

Higher tube side heat transfer coefficient;

Gentle, mostly vacuum evaporation and short residence times yield best - quality products;

Flexibility in Capacity and Operation.