LIST

PRODUCTS

Contact us

Wet Scrubber

- Tianli

- China

Equipment Structure

Equipment Structure

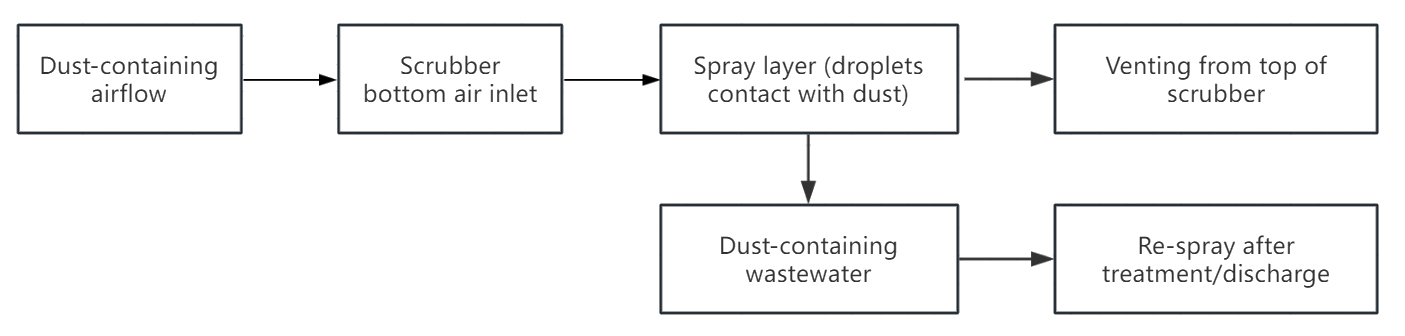

The wet scrubber is a wet dust removal device that achieves dust purification through gas-liquid two-phase contact. It uses the full mixing of water and dust-containing gas to capture, condense and separate dust particles by liquid. Its working principle is based on the synergy of multiple mechanisms. Inertial collision: Dust particles deviate from the airflow trajectory due to inertia, collide with droplets and are captured; interception effect: Dust with larger particle size directly contacts the surface of droplets and is adsorbed; diffusion effect: tiny particles contact droplets through Brownian motion; condensation effect: droplets make dust particles moist and agglomerate, forming larger particles for easy separation.

Key Structural Components

Tower structure: cylindrical tower, mostly made of carbon steel lining, stainless steel (corrosive working conditions) or PP (low temperature scenes); internally set with air inlet distribution plate, spray layer, packing layer (optional), demister and other components.

Spray system: spray layer is equipped with atomizing nozzles (such as spiral nozzles, solid cone nozzles) to atomize the liquid into fine droplets; circulating pump drives liquid circulation, and the flow rate is adjusted according to the processing air volume.

Demisting system: baffles, wire mesh demisters or swirl plates are used to remove droplets carried in the purified gas to prevent the “water carrying” phenomenon.

Technical Features

Advantages | Specific Presentations |

Multifunctional collaborative purification | It can not only remove dust, but also absorb acidic gases (such as SO₂, HCl) and remove oil mist, and is suitable for working conditions that require complex purification. |

Adapt to complex working conditions | It can handle high-temperature flue gas (directly spray water to cool down) and sticky dust (avoid blocking of dry dust collector); |

High security | No static risk, suitable for flammable and explosive dust. |

Moderate investment cost | Simple equipment structure and low initial investment (especially for large air volume processing scenarios). |

Key Influencing Factors and Control Measures

Liquid-gas ratio: Refer to the amount of liquid corresponding to a unit volume of gas. Improving the liquid-gas ratio can improve dust removal efficiency, but energy consumption increases. Tianli determines the optimal air volume value through experiments;

Spray pressure: The working pressure of the nozzle affects the droplet size. The higher the pressure, the better the atomization effect and the fine particle capture efficiency. Tianli uses a reasonable atomization nozzle to reduce the droplet size and improve the fine particle capture efficiency;

Air flow velocity: Too high a flow velocity in the tower will shorten the gas-liquid contact time, while too low a flow velocity will increase the equipment volume. Tianli selects a reasonable tower diameter through calculation and adjusts the flow velocity in the tower.

Application

It can be used to treat dusty exhaust gas discharged from fluid bed dryers, spray dryers, flash dryers, rotary dryers, etc. It is also suitable for high-temperature, high-humidity exhaust gas containing organic solvent vapor (VOC) or odor. It can remove water-soluble dust or sticky dust generated during the drying process. It can be used for smoke treatment of rotary kilns.

It can be used for the following materials:

Nickel-cobalt-manganese ternary materials, lithium iron phosphate (manganese), lithium carbonate, lithium chloride, lithium sulfate, lithium hydroxide, lithium dihydrogen phosphate, refined salt, soda ash, sodium sulfate, baking soda, calcium chloride, sodium percarbonate, ammonium chloride, ammonium sulfate, coal slime and other materials for dry tail gas treatment.