LIST

PRODUCTS

Contact us

Ordinary Fluid Bed Dryer

- Tianli

- China

Main Introduction

Main Introduction

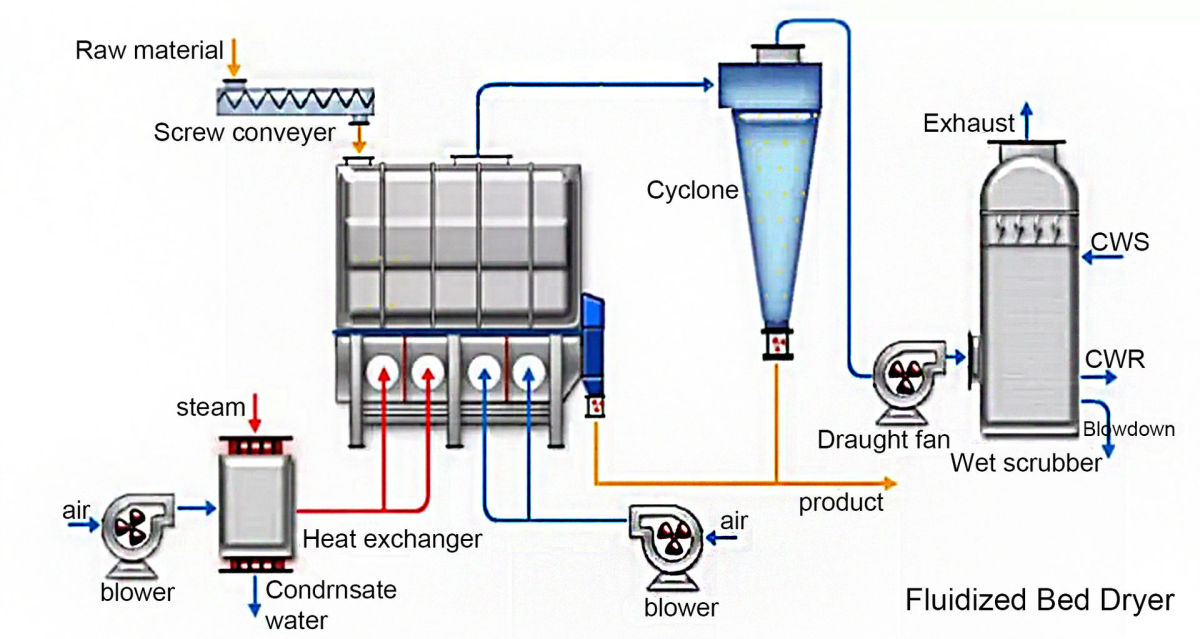

In the fluid bed dryer device, air is evenly distributed through the fluid bed dryer air distribution plate and then enters the bed layer, so that the material particles are suspended and fluidized. The fluidized material particles are fully in contact with the air flow, and strong heat and mass transfer is carried out, providing an ideal operating environment for drying or cooling.

The fluid bed dryer air distribution plate adopts the side-outlet pressure strip air distribution plate structure, which has uniform air distribution and average pressure, and can effectively prevent channel flow; its oblique air outlet pushes large pieces of material to the discharge side, making it difficult for the material to accumulate on the air distribution plate, reducing the occurrence of the air distribution plate blocking, and greatly enhancing the continuity of system operation.

Working Principle

The fluid bed dryer is divided into the upper and lower bed body, air distributor, the inlet and outlet ports, etc., and the wet material entering the fluid bed dryer is in contact with the hot air above the air distribution plate, and the material particles are suspended in the air flow to form a fluidized state. The material and the hot air are heat-exchanged and dried, and the finished product is discharged from the discharge port of the fluid bed dryer, and the dust-containing gas is purified by the dust collecting device and then discharged into the atmosphere by the induced draft fan.

Specification

Type | Bed Area(㎡) | Dehydration Capacity | Installed Power(kw) | Air Volume((m³/h) | Inlet Air Temperature(℃) | Dimensions(Length × Width × Height)(mm) |

GWL3.0 | 3 | 100~450 | 25~50 | 3000~15000 | 80~250 | 4000×1000×5000 |

GWL5.0 | 5 | 200~800 | 40~80 | 5000~25000 | 80~250 | 4000×1500×5000 |

GWL8.0 | 8 | 300~1200 | 70~125 | 8000~40000 | 80~250 | 7000×1500×6000 |

GLW10.0 | 10 | 400~1500 | 80~160 | 10000~50000 | 80~250 | 7000×1800×7000 |

GLW20.0 | 20 | 800~3000 | 150~320 | 20000~100000 | 80~250 | 13000×1800×7000 |

GLW30.0 | 30 | 1500~4500 | 250~500 | 40000~150000 | 80~250 | 15000×2000×7000 |

GLW45.0 | 45 | 1800~7000 | 380~750 | 45000~230000 | 80~250 | 13000×4200×7000 |

GLW60.0 | 60 | 3000~9000 | 480~950 | 60000~300000 | 80~250 | 15000×4200×7000 |

GLW80.0 | 80 | 4000~12800 | 650~1200 | 80000~400000 | 80~250 | 20000×5000×7000 |

Characteristics

1. Simple structure, convenient overhaul.

2. Simple steady operation.

3. The air and solid contact evenly with high thermal efficiency.

4. Low expenses of equipment maintenance.

5. Capable of lower temperature drying for the heat sensitive material.

6. Integration of drying and cooling bed, small floor space, low investment.

Applicable Materials

Widely applied in chemical, mining, pharmaceutical, food, feed, industrial and municipal sludge treatment industries. Example: choline chloride, sodium bicarbonate, alum, potassium chloride, magnesium sulfate, feed yeast, adipic acid, ammonium nitrate, calcium chloride, calcium hypochlorite, potassium carbonate, potassium sulfate, sodium carbonate, sodium hydrogencarbonate, sodium metasilicate, potassium nitrate, PVC, CPE, PC, etc.