LIST

PRODUCTS

Contact us

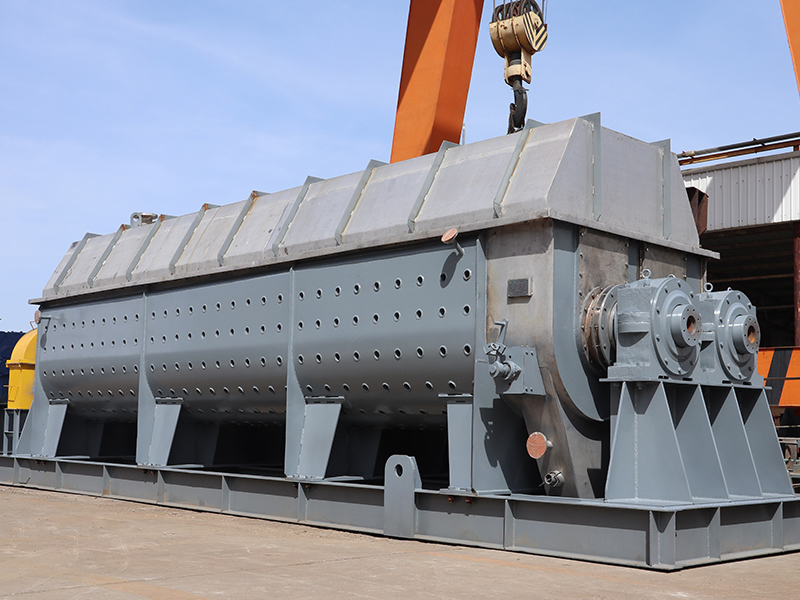

Paddle Dryer

- Tianli

- China

Main Introduction

Main Introduction

Paddle dryer is an indirect conduction heating type drying device, which is suitable for processing materials with good thermal stability such as paste, powder and granular. After special configuration, it can be used for processing heat sensitive materials, materials that need recover solvents during drying process and materials that need to be dried under rough vacuum. At the same time, paddle dryer can also be used for cooling of powder and granular materials and cooling and crystallization of some special materials by injecting cooling medium. It also can inject heating medium for heating materials and reactor to be heated.

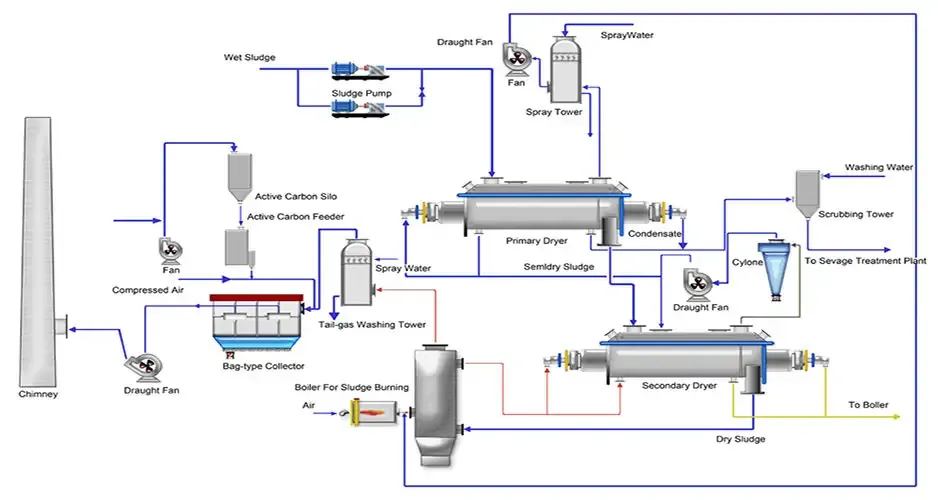

Working Principle

In the jacket shell body of paddle dryer there are two parallel shafts which have interleaved paddles. Each shaft has several hollow fan-shaped paddles which interleave with a certain spacing. There are two kinds of paddles: feed shear plane and return shear plane, the shaft rotates at low speed. A heating medium enters the hollow rotary shafts and paddles through a universal revolving joint. After heat transfer and drying, it is discharged through the revolving joint. The material is continuously fed into the equipment, next it is agitated and mixed near the paddles. At the same time, the material is gradually dried by the heat conduction of paddle and jacket.

The paddle dryer casing is a jacket structure, which can continuously provide heat for the drying process. The residence time of the sludge can be controlled by adjusting the motor frequency of the paddle dryer and the height of discharge baffle plate, thereby controlling the drying capacity and the final moisture content of the sludge within the desired range. The upper casing of the paddle dryer is equipped with a hot air inlet, where hot air enters the dryer to promptly remove the evaporated moisture during the drying process, and exchanges the heat with the surface materials for drying.

The transmission device is generally selected as motor - coupling - reducer - chain - main and auxiliary gears. The reducer is a hard-toothed helical gear box-type reducer, which is used for low-speed and heavy-load transmission and can bear large torque. The small sprocket is supported by a separate bearing seat instead of being directly installed on the output end of the reducer, effectively protecting the reducer.

Specification

Specification | Heat Transfer Area(m²) | Water Evaporation Quantity(kg/h) | Effective Volume(m³) | Installed Power(kw) | Speed (r/min) | Dimensions | ||

L | W | H | ||||||

CD250 | 6.2 | 30~60 | 0.25 | 2.2 | 5~15 | 4300 | 720 | 900 |

CD400 | 14 | 70~140 | 0.94 | 11 | 5400 | 1050 | 1260 | |

CD600 | 30 | 150~300 | 2 | 22 | 7200 | 1300 | 1800 | |

CD800 | 70 | 350~700 | 5.1 | 45 | 9900 | 1840 | 2300 | |

CD900 | 90 | 450~900 | 7.4 | 55 | 11000 | 1920 | 2290 | |

CD1000 | 110 | 550~1100 | 10.5 | 90 | 12500 | 2050 | 2700 | |

CD1200 | 150 | 750~1500 | 15 | 110 | 13200 | 2450 | 3200 | |

CD1400 | 190 | 950~1900 | 20.5 | 110 | 14500 | 2710 | 3630 | |

Characteristics

1. It adopts conduction type of heat transfer, the heat transfer efficiency is high;

2. The self-cleaning function of the heat transfer surface is good;

3. The product quality is stable;

4. The material loss is small, the product recovery rate is high;

5. The material adaptability is broad, the product is dried evenly;

6. It can combine drying and cooling together;

7. The equipment with compact structure occupies small area;

8. The design is unique, and maintenance of the equipment is easy.

Applicable Materials

Widely used in chemical, mining, metallurgical and other industries, such as ore, gypsum, coal, metal powder, diatomaceous earth, kaolin, and various of sludge drying, municipal sludge, paper sludge and other drying.